Vertical cutting plotter-GR8000-180

GUNNER GR8000 series of plotters offer a perfect solution for sign making, pattern proofing, die free contour cutting and custom production. It is capable of many different kinds of cutting soft and medium density materials. GR8000 is widely applied in various industries like advertising, graphics, shoes & clothes proofing, traffic signs, prismatic reflective sheeting,cutting protective films for mobile phones, autos, industrial products/films for exhibition and thick cardboard for package, vinyl sticker and magnetized logo, sandblasting protective films/ Photographic paper ,etc. New features like USB file transmission and one-click bar-code reading are user-friendly features for many different applications.

|  |  |

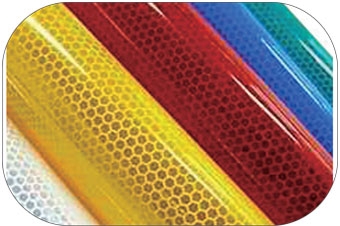

| Vinyl Sticker | Heat Transfer Vinyl | Reflective Sticker |

|  |  |

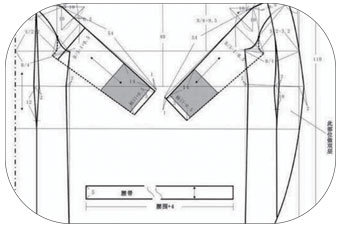

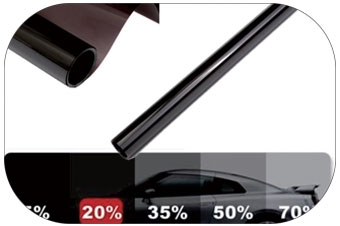

| Paper for Garment | Automotive Window Tinting | Photo Paper |

FeaturesSpecifications

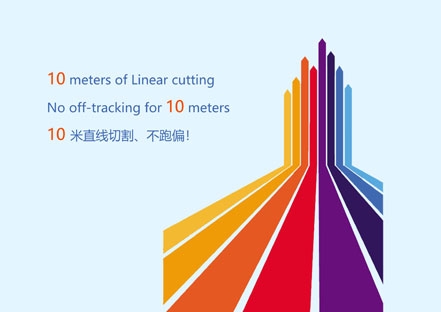

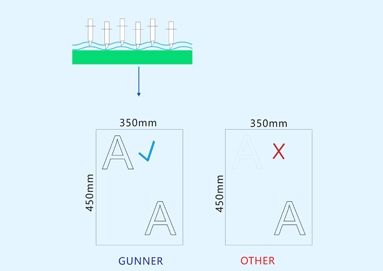

| The combination of precise material feeding rollers and quality media stocker ensure long stable linear tracking of material,the machine is able to feeds 10 meters straightly. The pinch roller is available with 2 levels of pressure adjustment. |

| Max. Speed: 800mm/s Advanced algorithm of motion controller,optimized tool paths,servo motor on X,Y, voice coil motor on Z and quality precision driving system,all of these elements make the machine moving faster and processing with more efficiency. |

| Max. Speed: 800mm/s Advanced algorithm of motion controller,optimized tool paths,servo motor on X,Y, voice coil motor on Z and quality precision driving system,all of these elements make the machine moving faster and processing with more efficiency. |

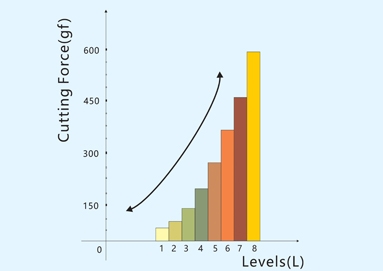

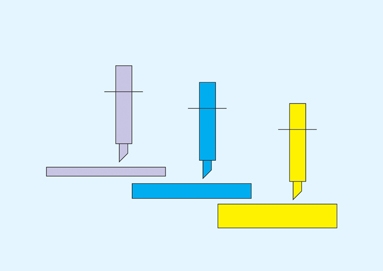

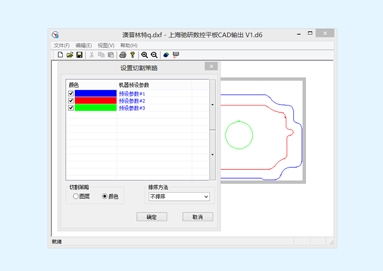

| The cutting force is subdivided to 8 levels and different levels come with different colors, the processing order is corresponding to color order. |

| Half cut and or perforation cut functions are available,user is able to perform either half cut or perforation cut ,user can also execute both of them within every single processing cycle. |

| Different cutting forces are applied to cut material with multiple layers, different cutting forces are inter-changeable to each other automatically for different layers . |

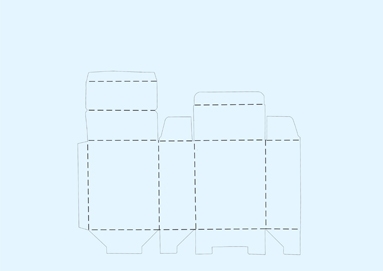

| Dotted lines cutting is available with Gunner’s machinery, this feature is especially useful cutting films with 2 layers and kinds of paper. |

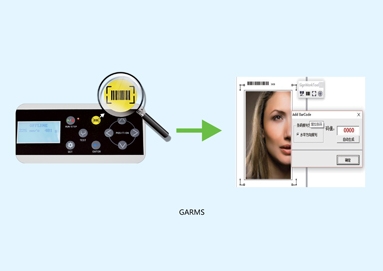

| USB(U flash memory) / Bar-code function One-click feature to identify the cutting job from each other by scanning the bar-code which is attached to cutting job. It is not required to connect the machine to computer when doing that,because Gunner machinery is able to read the bar-code/cutting job which is saved at a USB flash memory,which means more convenient off-line processing. |

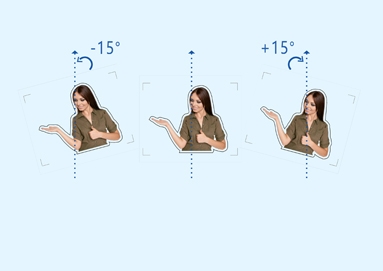

| Advanced Registration Marks Sensor /ARMS Gunner has his own software to generate contour in just one -click, and registration marks are setup conveniently as well. A Red laser sensor is applied to identify those marks quickly and then the contour cutting is ready to go. To identify the registration marks,it’s no need to let the cross of red laser close to the center of the marks as much as possible manually but just just put it around the mark,then the sensor goes to find the center of mark by itself. More importantly, operators just need to drive the sensor to the place around the first mark,then the machine goes to identify all of the marks by itself. Fine adjustment of the relative position between cross of red laser and registration marks with software is available. If material/contour is placed askew(≤15°),the machine system is still able to work fine, so it is unnecessary to put material/contour always horizontally and vertically,this feature helps alot to save time. |

| One-click to install print driver which is compatible with Window 32/64bit, it is able to send the cutting job by any CAD software that comes with printer feature. |

| Signworkpro,one of Gunner’s plugin software, is compatible with CorelDRAW and Adobe Illustrator , once the Signworkpro is embedded ,the CorelDRAW and Adobe Illustrator are able to identify the Gunner machine automatically via USB interface,thus the communication is set seamlessly and the cutting job travels between them smoothly. Signworkpro and other software own by Gunner offer diversiform solutions for different industries. |

| CAD Output Center It is allowed to output multiple levels of cutting forces in one time,thus the half cut,perforation cut and cutting media with multiple layers are realized. Advanced algorithm helps to optimize the tool paths, and then the work efficiency is improved significantly. |

| At CAD output center,operator is enabled to send the.DXF file to machine directly, while no need to transfer the file format. |

| One-click deletion button for the currently print document.Data is transmitted by USB flash memory,repeated operation is supported. |

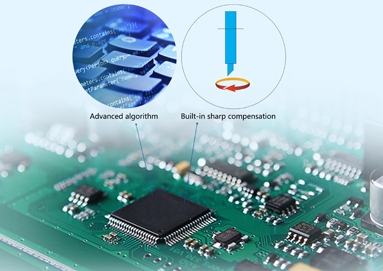

| We program and make the core of the machine,both software and hardware.Gunner’s controller/CNC runs with advanced algorithm,easy to upgrade and custom-made for different applications for future as we own it. Unlike the others, our system makes sharp compensation by hardware (main board) instead of software(PC&CAD/CAM software), our machine works at sustainable high precision no matter what kind computer system or CAD/CAM software is taken. |

| Carriage is one of the most important part of the machine.Taking the sport car structure, driven by silent voice coil motor,Gunner’s carriage is featured as fast speed,more agility and no overheat for long-term non-stop operation. |

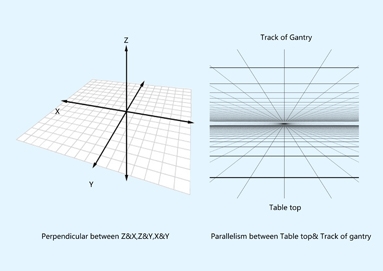

| Industry leading technology is applied to calibrate the perpendicular between different axes and the parallelism between track of gantry and table top. |

| It is inevitable that the table top or material surface is not at the same height from point to point,we take grating ruler,a precise optical device, to measure the distance between blade tip and material surface in real time, and the cutting depth is adjusted in every 0.01mm by the controller in real time according to the values of distances measured.Subsequently,the blade travels up and down as material surface goes up and down in order to keep the same cutting depth at any position of that tool path across entire working size. |

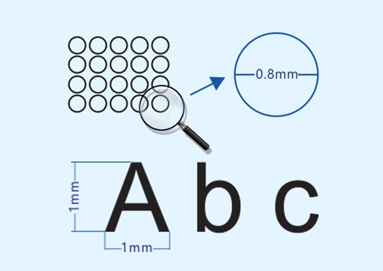

| The Gunner machine is featured as high precision, it is easy to cut circle with diameter as little as 0.8mm or letters sized 1x1mm, while the cutting edge is smooth,neat and no distortion, operator is able to tear off the scraps conveniently. |

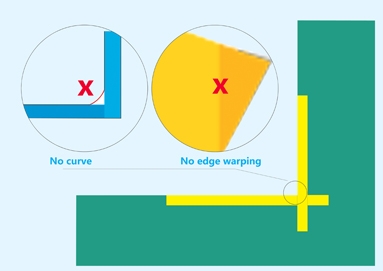

| An accurate machine has to be able to cut the right angle sharply, with the work piece by Gunner cutter,people don’t see any cure or edge wrapping. |

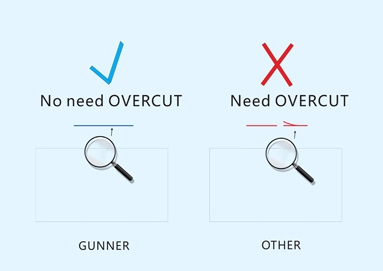

| Thanks to the advanced controller,Gunner machine cut with high precision with the accurate coincide of start point and end point while no need any OVERCUT. |

| To eliminate the static interference, Gunner machine has gone through year-round tests in different environment of different seasons. |

| For more outstanding performance and long-term reliable working, We only use world class brand name components such as BANDO belt,MINEBEA bearing,PMI linear guide-ways,etc.This means that you can always source these components on Google from local and competitive suppliers. |

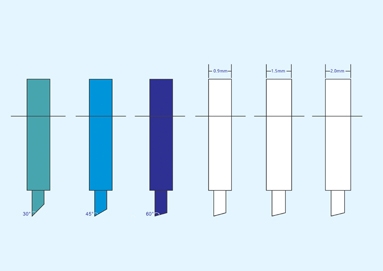

| There are series of cutting blades available with our machine,operators choose different blades according to different situations. Angle:45° / Diameter:0.9mm for Vinyl media Angle:45° / Diameter:1.5mm for Thick media Angle:30° / Diameter:1.5mm for Thicker media or smaller character Angle:45° / Diameter:1.5mm for High intensity reflective film Ball pen is also available. |

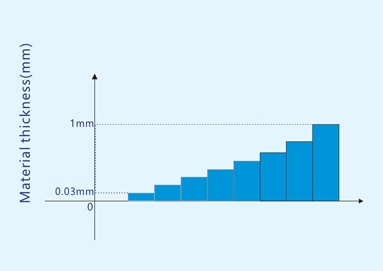

| Gunner cutter is applicable with: Materials with thickness 0.03-1mm. Card paper ≤ 500g/㎡ PVC thickness ≤ 0.7mm PET thickness ≤ 0.35mm And more materials.... |

Specification

| Model | GR8000-180 |

| Max.Cutting Width | 1690mm |

| Min.Media Width | 50mm |

| Max.Cutting Speed | 800mm/s |

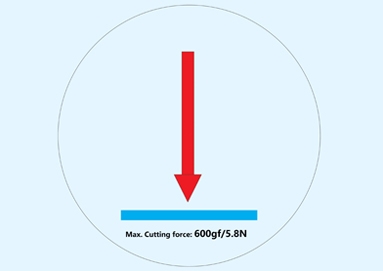

| Max.Cutting Force | 600gf/5.8N, sub-divided into 8 levels |

| Cutting Force Setup | Adjustable in every 1gf |

| Drive | Servo |

| Mechanical Resolution | 0.0125mm |

Min.Letter Size | 1x1mm |

| IOS | Win10/8/7/XP |

| Memory Buffer | 2MB |

| Software | Windows Driver, SignWorkPro ,CADtoPlotPro |

| LCD | English |

| File Format | HP-GL ,PLT |

| Port in Standard | USB,RS-232 |

| Registration Marks Detection | GARMS |

| Power Input | 90v-240v AC,50-60Hz |

| Power Consumption | 60w |

| Number of Tool Holder | One blade holder,one drawing pen holder |

| Cutting Blade Diameters | 0.9mm,1.5mm,2.0mm |

| Cutting Blade Angles | 30°,45°,60° |

| Types of Pen | Water based fiber-tip pen & Oil based ball pen |

| Method to Fix Material | Vacuum table and or Adhesive mat |

| Media Stocker | Included |

| Basket | For option |

| Package Size W-L-H | 2130x360x490mm |

| Gross Weight | 58kg |